Aluminium Electrolysis

Cell Technology

What We’re About

Alucelltech Inc. provides proprietary technology to improve the performance of all electrolysis cells which use pre-baked anodes and/or prebaked cathodes.

Aluminium Electrolysis with prebaked anodes operate in a narrow range of current efficiency (~88-95%), with power consumption typically 12,500-14,500 Kwh/mt.

Current efficiency is below 100% due to aluminium oxidation in the molten bath layer which may be caused by high bath superheat temperatures, magnetic field induced turbulence (waves & stirring) of the metal layer, and low and high voltage anode effect events.

Power consumption is high due to excess electrical resistance (measured as voltage drop) across the various materials and their interface contact resistances.

Cathode life of each cell is typically ~1800-2500 days, reduced due to high local current density at the ends, causing electrochemical corrosion.

Premature refractory failure of the sidewall is due to its direct exposure to molten aluminium when the frozen bath lining (ledge) is not maintained by adequate heat removal through the sidewall.

Technology to improve the performance of Aluminium Electrolysis Cells

Anode Nails

Anode nails – Anode nails reduce the electrical contact resistance between the anode assembly’s cast iron and carbon anode, known as the ‘Stub to Carbon’ STC resistance or voltage drop. Due to the >3% solidification shrinkage of cast iron during the anode assembly, the STC resistance during the life of the anode will depend on the contact pressure between the cast iron ‘ thimble or ring’, and the anode stubhole sidewalls. Anode nails are pre-installed in the stubhole wall prior to casting the iron, which nails conduct current across the iron to carbon interface with little contact resistance.

Benefits of Anode Nails include:

- Low electrical resistance across the STC connection which is unaffected

by iron shrinkage or stub wear. - Lower operating stub temperature to reduce anode air burn, stub wear and

stub toe-in. - Reduced variation in anode resistance between new and old anodes,

thereby improving current distribution among anodes for improved current

efficiency, lower potnoise and potentially lower PFC emissions.

Cathode Nails

Cathode Nails reduce the electrical contact resistance between the cathode assembly’s cast iron and carbon cathode. The current distribution is uneven through the length of the cathode collector bar cast iron connection, causing horizontal current flow through the molten aluminium layer prior to passing through the cathode to the collector bar. This horizontal current flow in the metal layer causes high current density through the outboard ends of the cathode, which promotes premature cathode corrosion, and causes magnetic field induced turbulence of the molten aluminium layer causing pot noise. Cathode nails and custom shaping of the cast iron connection enable a more uniform current distribution across the top of the cathode, to reduce cathode corrosion, extend cathode life, and to reduce pot noise for improved current efficiency.

Excavation of cathode nails, bridging the air gap.

Potshell Cooling

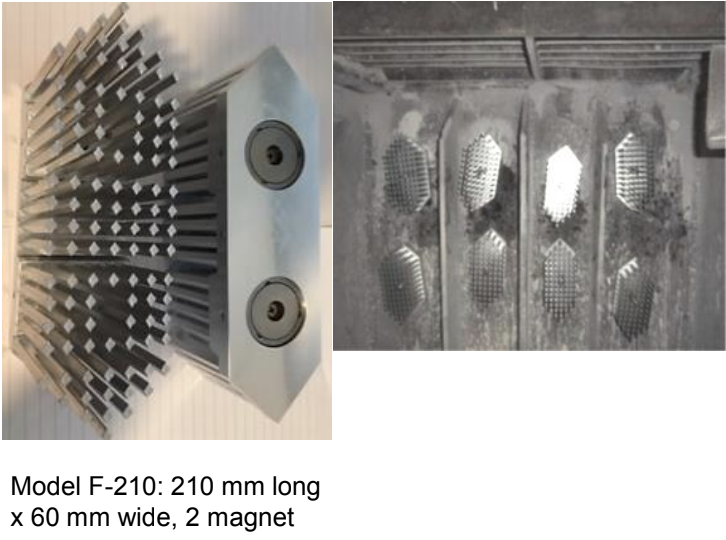

Magnetic Heat Sinks

Many pots operate at a high superheat from high amperage or low current efficiency, preventing the maintaining of a protective frozen layer of bath on the inside surface of the refractory. The magnetic potshell heat sinks can be easily attached to the external surface of the potshell to increase passive convective cooling of the potshell, aiding in maintaining an internal layer of frozen bath.

Potshell Magnetic Blankets

The corners of electrolysis cells have extra cooling compared to the non-corner areas of the pot, which may cause excessive internal frozen bath between the internal sides of the refractory cell lining and the corner anodes, causing interference in the mechanical movement of the anode support beam. The addition of magnetic potshell blankets, reduces the heat loss and aids in thinning the adjacent frozen bath layer to eliminate this interference and to reduce overall pot heat loss.

Two standard sizes of blankets are available, 150x300mm, and 300x300mm, which can be connected. Custom shapes and sizes are also available for a tailored fit. Different insulation thickness is available.

CONTACT AluCellTech 联系AluCellTech

For more information including samples, field trials, information, etc., please contact Sales at:

有关更多信息,包括样品,现场试验,信息等,请通过以下方式联系销售人员:

Voice, Mobile or Text: 语音,手机或文字: +1-905-330-9423

Email 电子邮件 : sales@AluCellTech.com

Wechat ID: wxid_isiqm95caxg522

Courier: Suite 104, Unit 6, 1500 Upper Middle Road West

Oakville, ON, L6M 0C2, Canada